More able to afford surgery, artificial joints, hips after launch of program

When orthopedic surgeon Yang Kaixiang started practicing at a hospital in Wuhan, Hubei province, in 2014, he met a patient who had to leave her severe osteoporosis untreated due to prohibitive medical costs.

"She was a migrant worker taking up gig jobs in Guangzhou, Guangdong province. She estimated that she had to work 10 years while living frugally to save enough money for a hip replacement surgery," said Yang, from the Wuhan Hospital of Universal Love.

In an interview in September, a decade later, Yang recalled how he could not help imagining the pain the woman had to endure.

In the past, despite the obvious risks of persistent pain and potential disabilities, it was not uncommon for patients to delay joint replacement surgeries because of hefty medical bills.

READ MORE: Centralized procurement cuts insulin prices by 48% in China

The procedure that replaces degenerated joints and hips with artificial ones could cost as much as 50,000 yuan ($6,800).

Today, thanks to a bulk procurement program led by the National Healthcare Security Administration, the price of such surgeries has significantly dropped.

The centralized procurement program, initiated in 2018, has managed to cut the prices of drugs and medical equipment through price negotiations with manufacturers who bid for large-volume contracts with public hospitals.

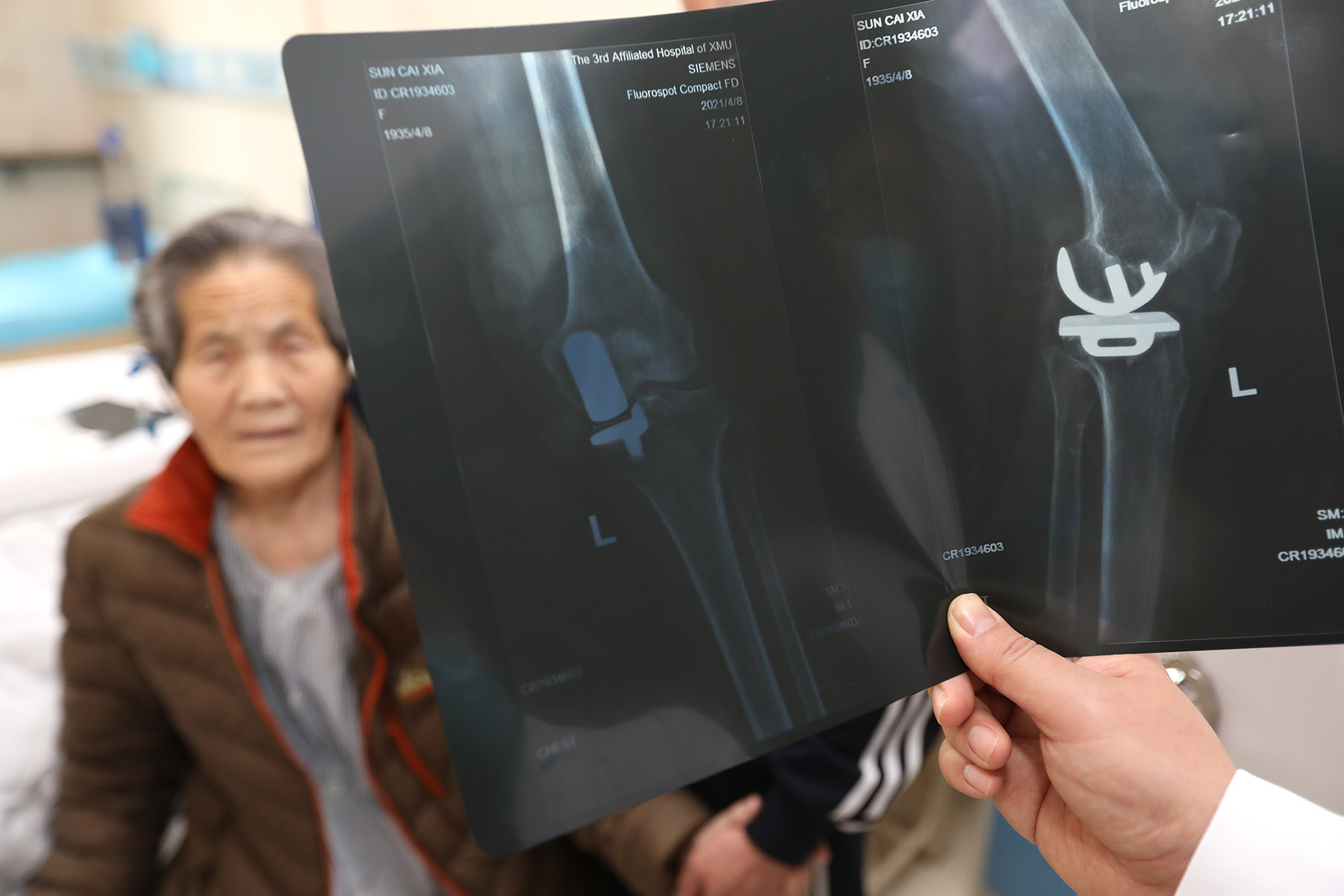

In September 2021, artificial joints were included in the national bulk buy drive as a swelling aging population had raised the incidence of osteoarthritis, rheumatoid arthritis and other age-related conditions, and propelled the demand for replacement surgeries.

The bulk buy campaign has cut the average price of artificial knees from 32,000 yuan to 5,000 yuan, and that of artificial hips from 35,000 yuan to 7,000 yuan.

Since prices were slashed in April 2022, more than 1.1 million products have been used, saving patients nearly 33 billion yuan, according to officials.

Zhang Zhongliang, a 44-year-old resident in Wuhan, checked out of hospital in early September, three months after having his right hip replaced.

"I was able to get out of bed and practice walking the day after surgery and resume normal activities about a month later," he said. "I was thrilled by the result and decided to get a second hip replacement as soon as possible."

Zhang was also surprised by the medical bill, which cost him about 15,000 yuan out-of-pocket per hospital stay. "My friend who underwent a similar surgery a couple of years ago said that he paid about 100,000 yuan more than I did," he said.

Data provided by the hospital shows that the number of spinal and joint surgeries carried out at the hospital from January to July this year had increased by 74 percent compared to the same period in 2019 before the COVID-19 pandemic.

At the same time, the total costs of artificial joints and other medical consumables such as titanium plates and screws dropped by 50 percent, and expenditures for medical consumables per surgery fell by 71 percent.

Cheng Wenjun, head of the hospital's orthopedic surgical center, said that in the past, he would identify six to seven patients in need of replacement each day during his outpatient consultations, but only one to two of them would end up receiving one because a large number of patients simply could not afford it.

"But nowadays, patients who reject surgeries mostly do so out of fear of the procedure itself and few are intimated by medical expenses," he said. "We have also seen the word-of-mouth effect as the elderly who are satisfied with surgery outcomes would recommend peers in their neighborhoods to seek help from us."

Cheng said the price reduction has expanded access to high-end products.

"At our hospital, 95 out of 100 hip replacement surgeries now use ceramic on ceramic bearings — the most advanced ones that promise low friction and low wear," he said.

"The price difference between advanced and regular ones at present is around a few hundred yuan, but before the bulk buy, the price gap was tens of thousands of yuan," Cheng added.

"Gradually, outdated models will be phased out."

The bulk buy program in 2021 saw 44 enterprises win bids, including 30 domestic manufacturers and 14 foreign companies.

Qin Jun, a surgeon at the Zhongnan Hospital of Wuhan University's department of orthopedic surgery, said that some patients have held grievances against using less expensive products and worried about their quality.

"It is important for us surgeons to communicate effectively with them. I would tell them that just like that homegrown electronics and domestic electric car brands have caught up on foreign rivals, the quality of domestic medical equipment has also improved to match or even exceed that of overseas products," he said.

Over time, he said patients have become more welcoming of procurement products and applauded the price cut.

Qin added that nearly all products in the procurement catalog are mainstream items from familiar brands.

"There are some cases, such as patients who experience lesions and thus require revision procedures as well as patients in need of customized screws or coating, where we need to look for products off the catalog, but such cases are rare," he said.

While patients' financial burden has certainly been relieved thanks to the program, concerns have lingered over whether the price slashing could hurt manufacturers' profits and dampen their motivations to enhance innovation.

Bao Shijun, general manager of Yijiabao, a biomedical company founded in Wuhan in 2014, said that the centralized procurement program has made it easier for the company to introduce its products into public hospitals.

"As an emerging enterprise in the industry, it would have been difficult for us to compete for contracts at major medical institutions. But through participating in the bulk buy, we have easily struck partnerships with hospitals and can focus on improving our products and services," he said.

The company has participated in every round of centralized procurement targeting medical consumables, including heart stents, artificial joints and spines, and artificial lenses since late 2020. Its sales revenue has been rising markedly for four consecutive years as of the end of last year and is expected to keep increasing this year.

Because the profit margin per unit has dropped, Bao said it is more than important to scale up manufacturing.

"In addition to joint products, we are looking to develop related materials to become a more comprehensive supplier," he said. "This year, we have also begun supplying our equipment in sterile packaging to make it more convenient for surgeons and meet emergency demands."

Mindray Orthopedics is a leading company in the industry with more than three decades of history.

Zhang Long, from the company's public affairs and marketing management department in Wuhan, said that the sector was highly profitable, so many manufacturers did not feel the pressure to streamline production and reduce unnecessary manufacturing costs.

Orthopedic surgeries also carry unique features. Some tools supplied by manufacturers are nondisposable and should be returned to storage for future use. For a single surgery, probably only a dozen out of 200 tools sent to the hospital will be used eventually, depending on the condition and physical shape of patients. As a result, the industry is confronted with complicated logistics issues.

ALSO READ: More bulk buys to further lower medical costs

Zhang said that the bulk buy program has motivated companies to explore innovative logistics solutions to cut costs, such as simplifying their network of supply chain agencies and establishing smart platforms to more efficiently track and manage the flow of equipment and consumables.

To satisfy the needs of sparsely populated and remote areas, Zhang said that the company plans to build more regional warehouses so that local partners can pick up products promptly and conveniently.

"In the future, we are looking to further ramp up our market share," he said. "One thing for sure at present is that the relatively disorderly competition in the orthopedic industry has been curbed."

Upon the two-year procurement agreement for artificial joints ending in April, the National Healthcare Security Administration initiated a new procurement bid in May.

Results show that 167 products from 54 companies were selected and the average price was further cut by six percent from the previous agreement.